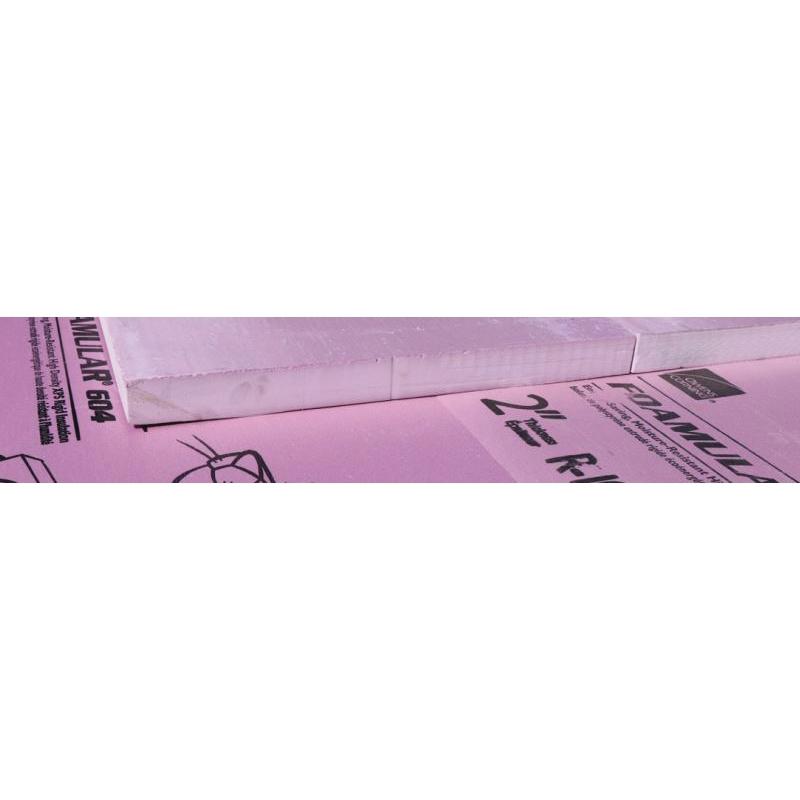

Rigid Board Owens Corning Unfaced 48"X96"X2" 32SF

Rigid Board Owens Corning Unfaced 48"X96"X2" 32SF

Manufacturer: Owens Corning

Brand Name: FOAMGLAS®

Part No.: IBF20400-SE

MPN: 270144

Min. Order Qty: 1

My Branch: Orlando FL

Owens Corning® FOAMULAR® & FOAMULAR® NGX® 400/600/1000 are high strength Extruded Polystyrene (XPS) Insulation products designed for use in engineered applications requiring additional load-bearing capability. It can also be used in tapered insulation systems.

FOAMGLAS® Rigid Insulation Board, 400 Series, 2 in Thickness, 4 ft Width, 8 ft Length, R-Value: R-5, 165 deg F, 40 psi Compressive Strength, Flexural Strength: 90 psi, Roof Installation, Polystyrene, Pink

| Color | : | Pink |

| Compressive Strength | : | 40 psi |

| Coverage Area | : | 32 sq-ft |

| Facing Type | : | Unfaced |

| Flexural Strength | : | 90 psi |

| Installation Type | : | Roof |

| Length | : | 8 ft |

| Material | : | Polystyrene |

| R-Value | : | R-5 |

| Series | : | 400 Series |

| Temperature Rating | : | 165 deg F |

| Thickness | : | 2 in |

| Width | : | 4 ft |

- FOAMULAR® NGX® XPS insulation are non-structural materials and must be installed on framing that is independently braced and structurally adequate to meet required construction and service loading conditions.

- FOAMULAR® NGX® XPS insulation can be exposed to the exterior during normal construction cycles. During that time, some fading of color may begin due to UV exposure, and, if exposed for extended periods of time, some degradation or "dusting" of the polystyrene surface may begin. Once covered, the deterioration stops, and damage is limited to the thin top surface layers of cells. Cells below are generally unharmed and still useful insulation.

- FOAMULAR® NGX® XPS insulation have a maximum service temperature of 165 deg F. Taking simple precautions during construction can minimize the potential for heat-related damage. Install only as much FOAMULAR® NGX® XPS insulation as can be covered in the same day. For horizontal applications, turn print side down when possible so the black print does not show to the sun, which may at times act as a solar collector, raising the temperature of the foam under the print to an unacceptable level. Provide a final finish covering or temporary white opaque covering to avoid possible damage when dark (non-white) surfaces are used over FOAMULAR® NGX® insulation. Do not cover FOAMULAR® NGX® XPS insulation either stored (factorywrapped or unwrapped), or partially installed, with dark-colored (non-white) or clear (non-opaque) coverings and leave it exposed to the sun. If improperly covered, and exposed to the right combination of sun, time, and temperature, FOAMULAR® NGX® insulation deformation damage may occur rapidly. See "FOAMULAR® Extruded Polystyrene (XPS) Insulation Heat Buildup Due to Solar Exposure Technical Bulletin" for more information.

- This product is combustible. A protective barrier or thermal barrier is required as specified in the appropriate building code.

- All construction should be evaluated for the necessity to provide vapor retarders. See current "ASHRAE Handbook of Fundamentals."

back To Top